TVS FlexFuel is the latest development from TVS Engineering in performance tuning technology. TVS is excited to be at the forefront of VAG performance tuning and shares their latest ECU tuning technologies with enthusiasts worldwide.

What is FlexFuel?

Flex Fuel allows a vehicle to operate on both regular Gasolines like 98RON and Ethanol fuels like E85 (and other Ethanol blends). The availability of Ethanol at gas stations continues to increase due to its sustainability and reduced emissions, and the potential for improved performance in which E85 is superior to pump gasoline. By adding an Ethanol sensor into the fuel system to report to the Engine Control Unit (ECU) the percentage of Ethanol measured in the fuel, FlexFuel operation is supported.

With FlexFuel, TVS can dramatically enhance the vehicle’s performance and retain maximum safety using the Ethanol sensor data and TVS’s new unique software package. Explained simply, more Ethanol content means increased performance. The best part? This is automatically and dynamically adjusted, thanks to TVS’s FlexFuel technology and an installed Ethanol sensor. Live data from this ethanol sensor is critical to safe operation, dynamically adjusting for deviations in ethanol content on-the-fly. As ethanol mixtures can vary depending on fuel station and time of year, the addition of an Ethanol sensor dramatically improves safety, always ensuring accurate fuel data is being always provided to the ECU.

✅ Increased performance

✅ Improved sustainability

✅ Optimized engine health and safety

✅ True Flex – Fully automated Ethanol operation

Why does TVS FlexFuel mean more performance?

When Ethanol is used as a fuel in performance applications, it is hard to overstate the benefits. Ethanol is the perfect fuel for high-powered applications with a dramatically improved octane rating, cleaner burn and a cooling effect.

Ethanol is the superior fuel choice for owners chasing more robust performance whilst also improving engine safety under high-performance applications. TVS FlexFuel allows for seamless operation when introducing Ethanol to your vehicle, allowing customers to enjoy the benefits regardless of application.

Let’s talk about E85

E85 is an 85% mixture of Ethanol (alcohol) and a 15% mixture of unleaded gasoline. Historically ethanol-based fuels were reserved for race applications due to its high-octane rating, cooling properties and more controlled burn. Thanks to its environmentally friendly and renewable nature and high-performance potential, E85 has become increasingly widespread and is now more available than ever.

The primary benefit of E85 is its improved octane rating of 105RON. Octane rating measures a fuel’s ability to withstand detonation or knock (uncontrolled ignition event). Excessive ignition advance at a given boost level can lead to detonation on non-ethanol pump fuels; this can cause reduced performance and, ultimately, engine damage. The low-octane nature of 98RON pump fuel often limits the power TVS can achieve safely. Increased octane rating, especially on high boost applications, allows for a safer and higher performance ceiling. This is why E85 truly is superior.

Alongside a much higher octane rating, E85 also has a very high latent heat of evaporation. When Ethanol is injected into the intake tract (port injection) or cylinder (direct injection), the injected fuel vaporises and cools down the intake air charge. This increases the charge air density and improves overall fuel stability and resistance to knock events (this is particularly valuable in turbocharged applications).

The FlexFuel Challenge

E85 is not as energy-dense as 98RON, requiring approximately 30% extra fuel by volume to achieve equivalent energy output. To unleash the full power potential, an upgraded fuel pump and/or injectors are often required to run E85 as the factory components cannot deliver and inject the extra fuel needed. After proper calibration of these upgraded components, it is not as simple as increasing fuel delivery by 30% at every load point; the solution must be significantly more complex to maintain the drivability, reliability, and performance characteristics TVS customers expect.

Having extensive experience with the SIMOS18 powered EA888.3 Engine on 98RON and E85 independently in all applications, TVS has total R&D completed with a broad array of hardware and fuelling configurations across a variety of EA888.3 platforms.

The challenge starts with integrating all of this unique R&D in a unified, flexible and reliable package that can be executed in various TVS FlexFuel use cases.

How TVS developed TVS FlexFuel

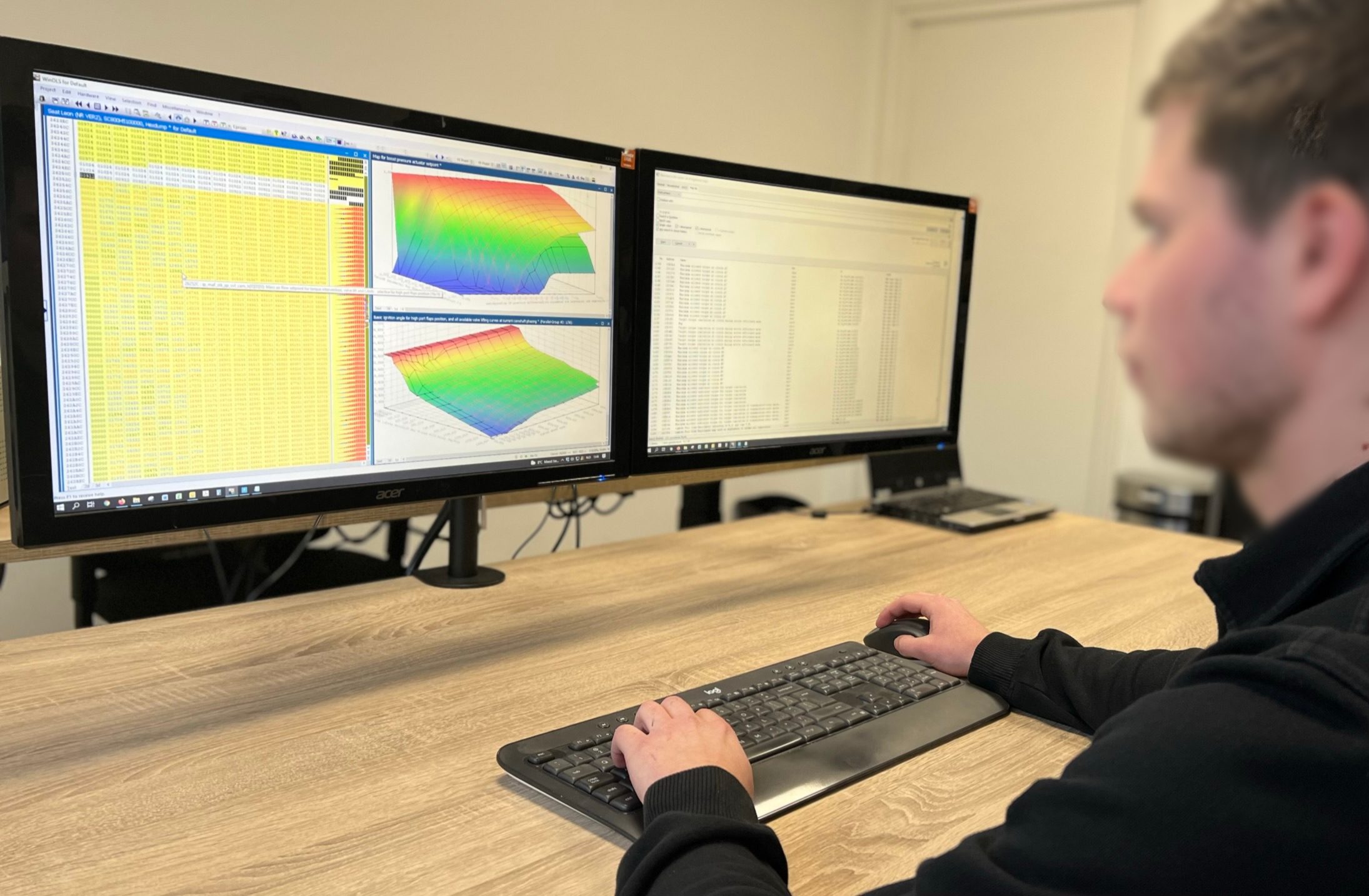

To begin the development of any vehicle’s new software functionality, it is critical to understand the calibration environment, hardware, software and their respective limitations. Extensive calibration and reverse-engineering experience on the SIMOS18 ECU ensured TVS had a solid foundation to start the TVS FlexFuel development.

Over TVS’s 10+ Years of operation, TVS has tuned thousands of SIMOS18-equipped vehicles and spent countless hours on calibration and code analysis. During the early stage of SIMOS18 development, TVS noticed some basic factory routines existed to determine the ethanol percentage in the fuel. As soon as it was clear there was market demand for Flex Fuel operation, TVS carefully analysed these existing routines.

First was verifying the available factory Ethanol fuelling routines and their functionality; this was imperative to ensure that these routines worked correctly and that the Flex Sensor integration was functional and reporting accurately to the ECU. After verification, the TVS R&D team made further modifications, allowing customisation of the available routines to support custom tuning in modified applications. Additional routines and tests were developed to test the failure states of this setup, such as a failed sensor, incorrect sensor reading, and water in fuel, all of which passed with flying colours.

With the fuelling component of Flex support completed, TVS built new routines to automatically adjust ignition timing according to the reported ethanol percentage. No factory software routines are available within SIMOS18 for adjusting ignition timing based on Ethanol content. TVS developed custom code, which TVS integrated with factory software enabling the TVS software calibration team to precisely tune ignition timing based on ethanol content. TVS rigorously tested this routine to ensure safe operation in all scenarios and failure states. TVS signed it off as the perfect solution for the TVS FlexFuel applications, operating as usual on 98RON and taking full advantage of Ethanol when introduced into the system.

To further improve the comprehensive nature of TVS FlexFuel, TVS also introduced a ‘boost by ethanol’ routine, allowing dynamic adjustments to target boost levels based on reported Ethanol content. Extensive R&D was needed to fully design, develop and implement this new custom code to provide functionality for TVS calibration engineers. These developments allow complete control over boost levels based on ethanol content. Comprehensive testing was undertaken in house by the TVS calibration engineers. Through a combination of data logging, data analysis, dyno- and street testing TVS was able to validate safe and effective operation.

The Boost by Ethanol routine gives the ability to run higher boost pressures on high Ethanol content mixtures. This is especially effective on high power applications where power on normal Gasoline is often limited due excessive exhaust gas temperatures.

In addition, the Boost by Ethanol functionality allows TVS to run production boost levels on Stage 2+ Flex applications when using 98RON and scale down the target boost levels when on Ethanol mixtures. This is to respect the fuelling limitations of the 2+ Flex Fuel setup ensuring full performance and safety no matter the scenario.

What is next for TVS FlexFuel?

In summary, TVS has built and implemented a new performance technology enabling thousands of enthusiasts worldwide to run and benefit from multi-fuel setups. Power ceilings are higher and safer than ever, with no compromise needing to be made. TVS has always set out to raise the limits of what is achievable for our customers, and believe that TVS FlexFuel is the next step in pursuing this goal!

What is next for TVS FlexFuel? You decide! What would you like to see?