SIMOS19 MQB EVO TECH POST – Downpipes

After the release of our ECU and TCU tuning solutions for the new 2.0 TSI EA888.4 EVO platform we decided to start sharing what is involved at TVS Engineering’s development program. We at TVS believe that providing accurate and valuable information is important to show our followers and customer base how deep we’ve dived into this new platform. In this tech post we will speak about downpipe upgrades for the 2.0TSI EA888.4 engine.

AFTERMARKET DOWNPIPES

To analyze the maximum restrictions of the 2.0 TSI EA888.4 factory downpipe TVS decided to install a Milltek large bore de-cat downpipe. These downpipes are fabricated with a larger diameter and bypass the factory catalyst and gasoline particulate filter (GPF), meaning that there is significantly more space for exhaust gas to exit the engine and pass through. This product is however suitable for off road / track use only since it won’t comply with emission regulations anymore in most countries.

Many of our customers often raises concerns about increased exhaust back pressure due to the catalysts and GPF’s downpipes are equipped with. However many researches and measurements show that during normal circumstances the backpressure caused by a properly designed catalyst and GPF are very minimal. Most of the back pressure caused by a GPF tends to be caused by the accumulated soot, rather than the filter substrate itselves. So the results we publish below normally won’t significantly differ to aftermarket downpipes with similar diameter and (sport) catalyst.

TEST EQUIPMENT

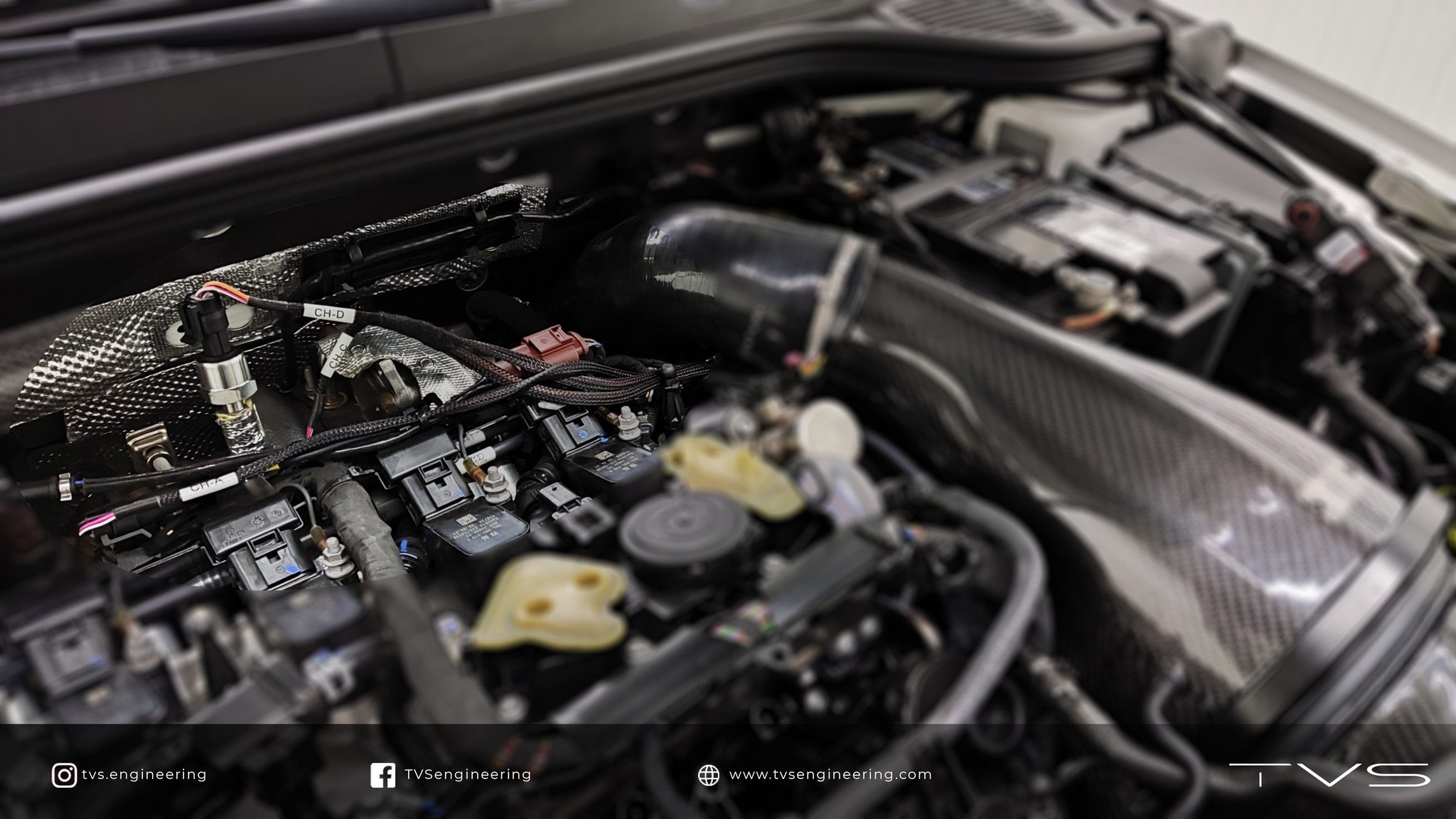

To proper test, analyze and compare the upgraded Milltek downpipe to the factory one our development Golf 8R is outfitted with additional sensors. Both exhaust gas temperature (EGT) and pressure sensors are installed in the exhaust manifold by our technicians to monitor pre-turbo EGT and engine back pressure.

Next to logging those data that cannot be monitored on stock engine management due to the lack of those sensors, this also gives our engineers the ability to validate the model based SIMOS19 software and further improve our tuning solutions. We at TVS believe this is required to operate at factory level and beyond for achieving maximum performance and drivability without sacrificing reliability.

RESULTS

The results we discuss below are retrieved on dyno from the TVS development Golf 8R where measuring conditions were kept similar at the start of every dyno run as much as possible. To further minimize the influence of environmental conditions within our dyno room mean values of three dyno runs are plotted.

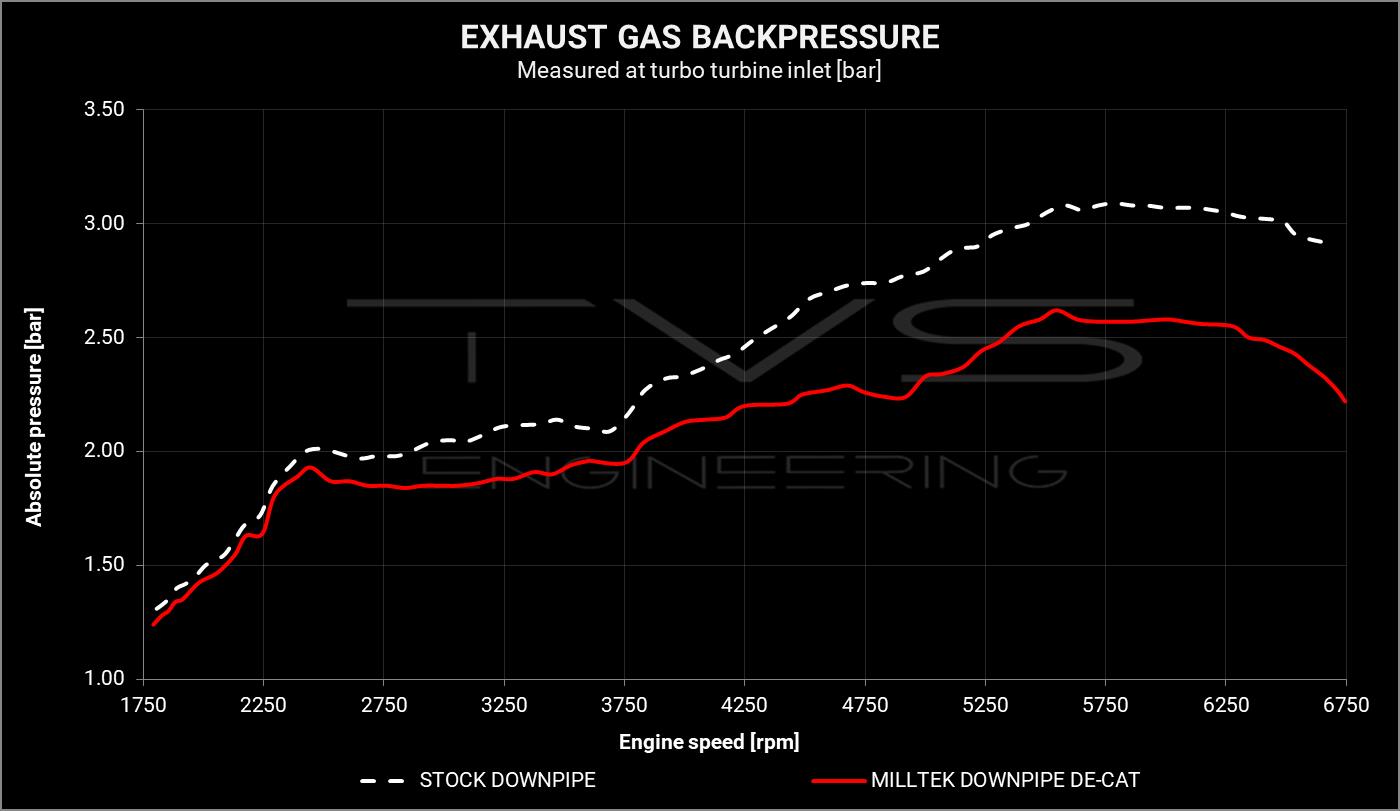

Exhaust gas back pressure

A proper designed downpipe guides the exhaust gas flow after leaving the turbocharger with as less as possible restrictions to the exhaust system. In general the larger the diameter of the downpipe, the easier the exhaust gasses can leave the turbocharger allowing more exhaust gas to flow through. In addition this will help reducing exhaust gas temperature.

As we can see in the graph below the Milltek de-cat downpipe is minimizing the exhaust gas backpressure over the entire engine speed range compared to the factory downpipe. Those measurements are performed with factory ECU software installed. Maximum backpressure drops up to 0.5 bar or 20% are achieved with the Milltek de-cat downpipe installed.

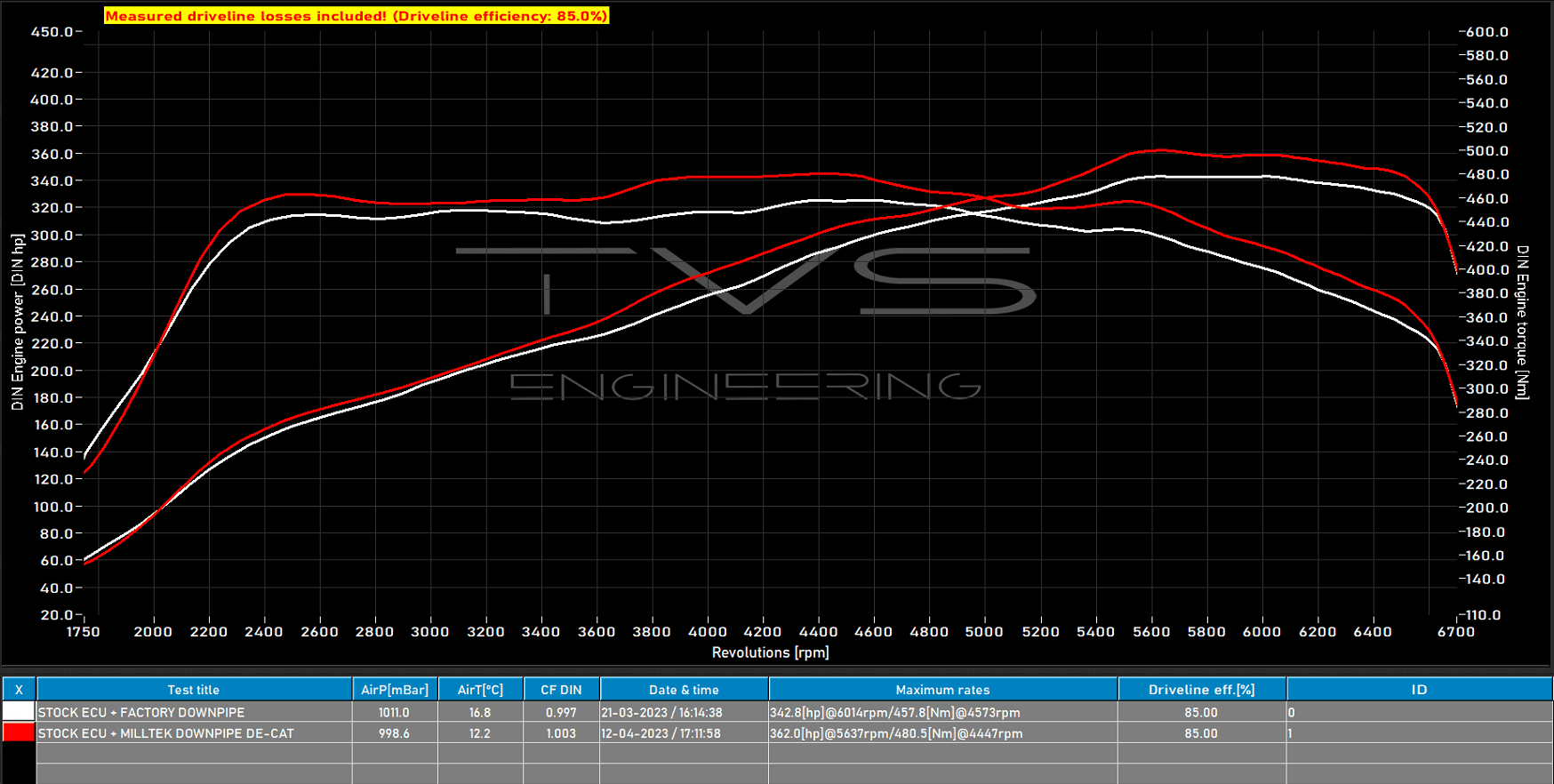

Dyno results

Let’s see if the retrieved data matches the performance measured on dyno. The performance numbers below are DIN corrected engine HP and Nm. The first graph shows the performance differences using factory ECU software. Next to the stock downpipe versus Milltek de-cat downpipe an Eventuri intake is installed on our development Golf 8R during both measurements responsible for already some extra performance over the factory numbers. As displayed below the Milltek de-cat downpipe results in an performance increase over the full range with peak gains of +19.2 HP and +22.7 Nm.

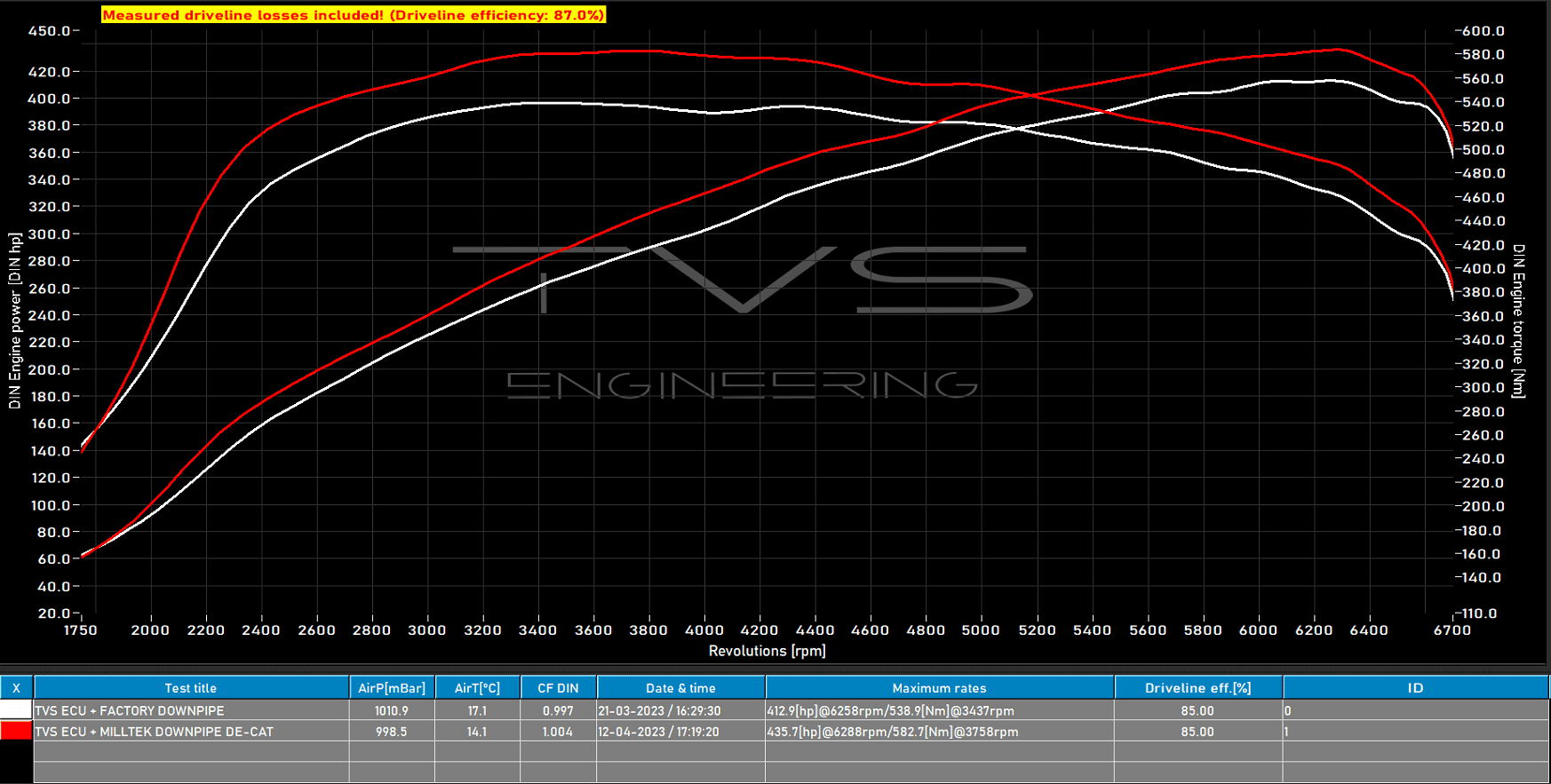

With TVS Stage 2 ECU software installed the benefits of the Milltek de-cat downpipe are even better noticeable. Performance increases throughout the entire engine speed range with peak gains of +23.7 HP and +45 Nm are very impressive. The additional installed pressure and temperature sensors show even truly reliable operation and gives our calibration team valuable data to push the 2.0TSI EA88 Gen4 platform to even higher limits. Stay tuned!